Product Introduction

Product Introduction

TECHNICAL PARAMETERS

| MODEL | ZPS100-10A | ZPS100-10B | ZPS100-10C | ZPS100-10D |

| Used for | Standard model | Anti-corrosive | ||

| Max working pressure | 1000KN | 1000KN | 1000KN | 1000KN |

| Max prepressing pressure | 200KN | 200KN | 200KN | 200KN |

| Max diameter of tablet | φ80mm | φ80mm | φ80mm | φ82mm |

| Max thickness of tablet | 28mm | 28mm | 30mm | 34mm |

| Max depth of filling | 58mm | 60mm | 66mm | 68mm |

| Dies | 10 sets | 10 sets | 10 sets | 10 sets |

| Max production capacity | 6600pcs/h | 6000pcs/h | 5400pcs/h | 4800pcs/h |

| Rotation Speed | 0-11 r/min | 0-10 r/min | 0-9 r/min | 0-8 r/min |

| Motor power | 22kw | 22kw | 22kw | 30KW |

| Power supply | 3P 380V 50HZ (can be customized) | |||

| Machine Weight | 7000kg | 7500kg | 7500kg | 8000kg |

Product Description

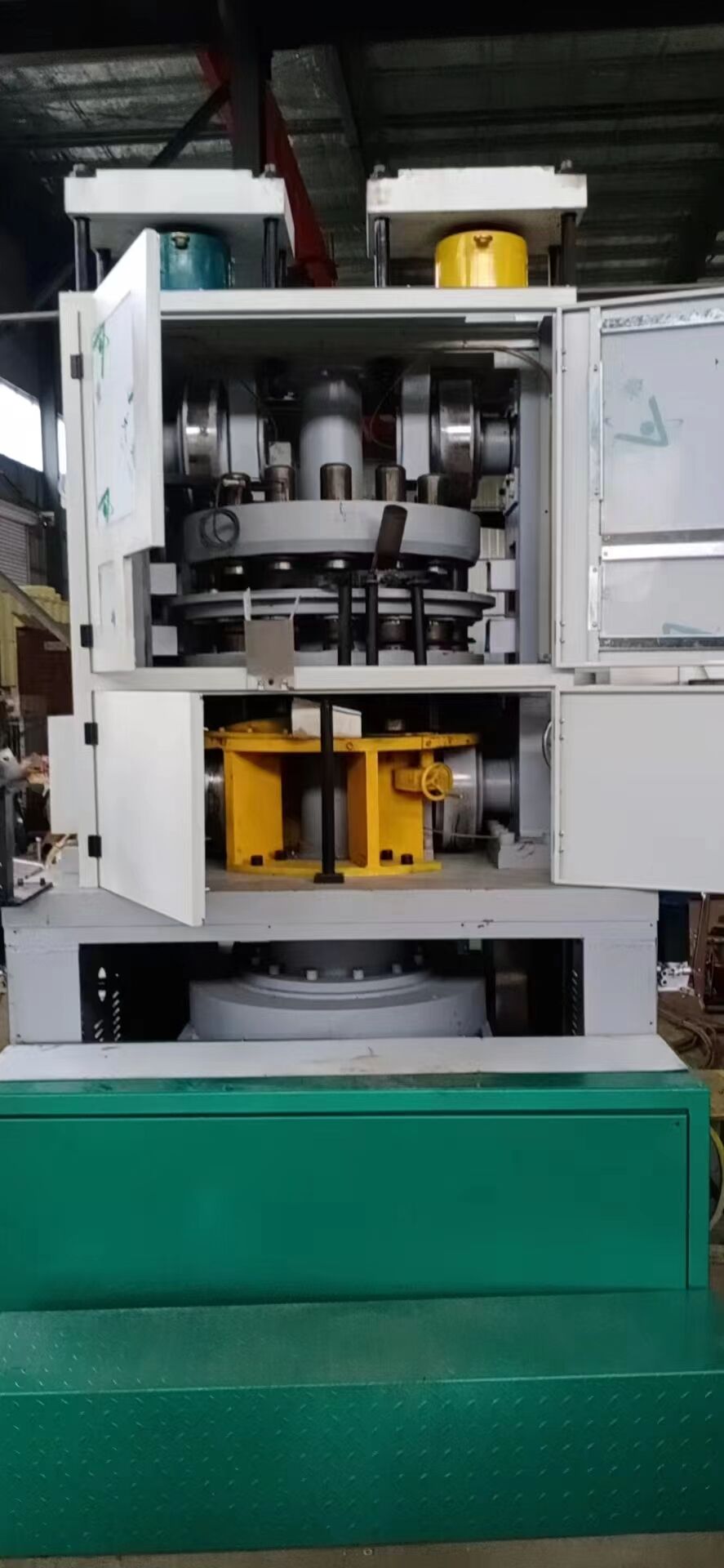

ZPS100-10 series tablet press is used for pressing TCCA, SDIC, alkali, aluminum sulphate, ceramic granule, chemical powder, bath salt, water purification salt and other powders and are mainly used in chemical, food and medicine industries. The tablet press has high precision, reliable performance, stable pressure, high yield. It can press annular, spherical and irregular shaped tablets as well as tablets with characters, logos and figures.

The mechanical drive part of ZPS100-10 is separated from the tablet-pressing room in order to prevent the materials from pollution when they are pressed. Automatic centralized lubrication system, special oil drain, dustproof, noise control system, the high-definition and isolation window design are equipped with the machine. There is no dead angle tablet room with all open structure and clean operation and easy maintenance. Unique four-pillar frame structure to ensure the machine stable and durable, which is steadier than 3-pillars(ZPS80-8A) so the machine can be operated smoothly, low noise. Mould's heat treatment process keeps pace with the world, has long service life. ZPS100-10 is equipped with spraying devices for demoulding agent (patent). It is suitable to press materials which is viscous or hard to be demoulded.

Company Profile

Qingdao Develop Chemistry Co. was established in 2005 in the coastal city of Qingdao, China. Owner and general manager Richard Hu has decades of experience with the chemicals used in the water treatment industry.We have specialized in water treatment and disinfectant chemicals for more than 20 years, providing products of excellent quality at a competitive and affordable price. We provide products of excellent quality and competitive price. The main products are Trichloroisocyanuric Acid (TCCA).Sodium Dichloroisocyanurate (SDIC), Cyanuric Acid(CYA).chlorine dioxide, etc.

Noted for our high quality products and professional service, we are a globalizing enterprise with clientele in 70 countries with promising and emerging markets in: France, Spain, Russia, Ukraine, Pakistan, Indonesia, Malaysia, Turkey, Vietnam and Brazil. In the past year, our company has sold more than 20,000 tons of products internationally. With powerful product design, development and material purchase, good experience at production and product distribution, we will become stronger and stronger along with the market.

Strictly abiding the business concept of “honest & creditable business, harmonious development”, the company has perfected the service system and the quick-responding mechanisms to provide all-round services for before, middle and after sales. The company periodically organizes and dispatches production and technical staff to visit customers, who are always ready to provide you excellent, professional and all-round services.

Please believe that we will be your best choice.

EN

EN